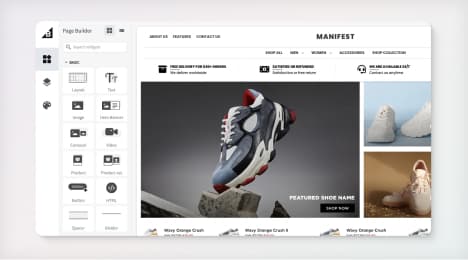

Watch Our Product Tour

See how BigCommerce helps you build and manage your online store with ease.

- Ecommerce Insights

6 Key Steps to Launch Your Online Store

Explore our Launch Foundations series to get your BigCommerce store up and running quickly.

BigCommerce helps growing businesses, enterprise brands, and everything in-between sell more online.

What is Multi-Warehouse Management?

Commerce is evolving. While some things have changed incomprehensibly, others never have. From the earliest days of merchants and traders, certain elements have held true. One of them? Inventory. It may seem like inventory management is a modern problem, but it’s one we’ve been dealing with since the birth of business.

In the late 1800s, Herman Hollerith invented the first punch card readable by machines, which marked the first innovation in inventory. This invention was a precursor to the computer, and Hollerith’s company went on to become IBM.

During the 20th century, innovation for commerce was totally transformed. In the 1930’s, the modern checkout system was invented at Harvard. And by the 1960’s the UPC or barcode system had been invented.

These great strides in the modernization of commerce have played a big role in the turn toward ecommerce. Modern technologies have allowed ecommerce businesses to grow exponentially. With that growth, comes a need to manage and control inventory at a much larger scale. Today, that scale comes in the form of warehouses.

Warehouses are essential for millions of businesses that rely on ready-made inventory to propel their operations. Once a business reaches capacity in its first warehouse, it needs to expand into another, or multiple if necessary. Of course, some businesses may start out with more than one warehouses or fulfillment centers for many different reasons, likely having to do with production and the location of their customer base.

Putting into practice: As an example, let’s say you’re an ecommerce retailer specializing in bridesmaids dresses. Your primary audience has historically been in the Southern US, with your warehouse in Florida. This year, you’ve added warehouses in California and Texas to meet a rapidly expanding customer base. Now that you need to manage multiple warehouses, you’ll need to keep an eye on the inventory stock of each one, plus track what customers are ordering from which areas of the country. Understanding and managing these decisions will be a large part of your multi-warehouse management work.

So how do businesses juggle both the inventory and operation of multiple warehouses? Keep reading to understand what multi-warehouse management is, what it’s good for, and what some of the most common challenges are.

Defined: Multi-Warehouse Management

Multi-Warehouse Management involves the management of operations in multiple warehouses. The term covers all operations, involving inventory, staff, shipping, storage and movement of goods. In the world of ecommerce, Multi-Warehouse Management has a more specific meaning, centered around the shipping and fulfillment of products from multiple warehouses, plus the related logistics. There are many reasons an ecommerce store would ship out of multiple warehouses.

Benefits of Multi-Warehouse Management

Having multiple warehouses inherently makes it cheaper and faster to ship to a wider area. But the benefits extend far beyond this. Implementing a system that effectively manages warehouse distribution provides a bevy of other benefits too, which will make order fulfillment more accurate, efficient and transparent.

One single point of truth

Unlimited warehouses

Real-time data

Locate and track inventory

Warehouse stock transfers

One single point of truth.

With effective multi-warehouse management, you have a reliable, constant source of accurate information about each of your warehouses and what’s inside them. This eliminates the need for individual warehouse management, which can leave data and details siloed within its own location. Multi-warehouse management means every piece of information about every one of your warehouses is indexed and easily accessible. This removes the need to relate different information from warehouses to one another across mismatched systems. Common issues with over and understocks, mismatched inventory levels and missed fulfillment deadlines are eliminated when multi-warehouse management is applied. Say goodbye to confusion, frustration and inaccuracies, and get acquainted with a single point of truth.

Putting it into practice: As a dress seller, you need full clarity into which collections are in stock in which warehouse. With mismatched information from different sources at the different warehouses, you might run into trouble. One issue could come from different quantity counts. If gowns in the Texas warehouse are stored and counted in single quantities, but the Florida warehouse counts a single unit as a package containing four of the same dress, you’re headed for trouble. Having a single source of truth applied to every product in every warehouse will give you clear and comparable data to work with.

2. Unlimited warehouses.

Whether your business is large or small, you can have as many warehouses or fulfillment centers as you need. Effective multi-warehouse management allows you to easily add and customize warehouse data, which then does the work for you from there.

There are a multitude of features and options you may require in your management solution, but the most vital function is the ability to fulfill orders based on individual order details. In other words, your warehouse management system must effectively communicate with your ecommerce platform to reap its benefits. A smart solution allows seamless links between every order placed, and every piece of inventory needed to fulfill the order.

Putting it into practice: With so many dress choices, you don’t want to be limited to a single or a couple of warehouses. As your line expands and grows in popularity, you need to have a scalable system in place. Perhaps in the coming months, you realize you need to open an additional warehouse in Michigan to serve midwestern customers. With an out-of-sync multi-warehouse management system, you’d be facing a massive task in adding a warehouse. With an effective system in place, however, adding a warehouse is simple and straightforward.

3. Real-time data.

The most valuable asset you’ll gain with multi-warehouse management is the accessibility of live, accurate data. When all warehouses use the same system, inventory and distribution runs smoothly.

When setting up your warehouse management, it’s vital to upload and sync all data accurately so everything starts from a place of certainty. With accurate data close at hand, you can monitor stock quantities and stock in transit, plus stay on top of updates, and changes within every warehouse. Better yet, with multi-warehouse management effectively implemented, you’ll be able to access order data in real-time, no matter the location of the fulfillment warehouse.

Putting it into practice: You’ve just released a new line of dresses in jewel tones. Customers are going crazy placing orders for entire wedding parties. Luckily, with multi-warehouse management in place, you can feel confident in inventory counts at each of the warehouses. Having useful purchase data in your back pocket, you’ve planned ahead for expected order volume, keeping in mind that your customers in California tend to need bridesmaids dresses throughout the summer months, while those in the South tend to order their dresses to be ready in the cooler spring or fall months. With this data coming in in real-time, you can make stock transfers, keep an eye on inventory count and gain valuable purchase data.

4. Locate and Track Inventory around the globe.

With full visibility into every order and every piece of inventory, there’s no more mystery surrounding current stock levels, order statuses or fulfillment logic. This affords you a single view of each warehouse and everything inside, giving you the full flexibility to fulfill items in the most efficient way possible. Finally, you have complete visibility over the location of every single product.

Putting it into practice: With manual inventory counts and mis-matched management systems, you might not know where your stock is at any given moment. Perhaps I know I’ve still got 800 of the new popular emerald gowns in my inventory, but with several having been purchased and returned, and still more having been undeliverable, it could be a challenge to track them all down. Effective inventory tracking eliminates this issue, and makes every piece of inventory traceable and manageable.

5. Warehouse stock transfers.

With effective multi-warehouse management, a transparent system offers clear insight into needed stock transfers. You’ll see real-time information on specific stock levels and order volume, giving you full control to transfer stock for timely order fulfillment. When an order is picked, the system is updated immediately, eliminating troublesome discrepancies and delays.

Putting it into practice: Need a shipment of dresses for a convention in Florida? Time to transfer stock. Seeing a spike in demand in LA? Send a few dozen top sellers that way. With full visibility, you’re better equipped to handle any exceptions or transfer needs.

Challenges Warehouses Face Without a Multi-Warehouse Management System

Without the right systems in place, merchants face a multitude of issues with regard to communication, inventory count and operational transparency.

Issues with cross-warehouse communications.

With warehouses operated by different teams, communication is bound to be a significant challenge. If separate warehouses operate on various management systems, insight into inventory, stock transfers, quantity tracking and any unexpected issues cannot be effectively communicated within the management system. It’s vital to set up points of contact and processes for communication within several steps of the fulfillment process. A warehouse can only operate as effectively as it’s set up to do. The more issues that happen within the warehouse, the higher the chance is that a customer will receive a late or inaccurate order, which is the worst case scenario for an ecommerce merchant.

2. Lack of oversight into inventory levels at all sites.

Without accurate and thorough oversight of inventory levels, every order placed leaves a merchant vulnerable to unforeseen delays and fulfillment issues. If stock is stored incorrectly, improperly identified, or simply misplaced, the management of any warehouse becomes significantly more complicated.

Discrepancies between purchase orders, storage locations or a number of different elements could seriously disrupt warehouse operations, even if it’s only occasional. By far, the most common issue warehouse managers face is inaccurate inventory counts.

3. Multi-Warehouse Rating.

Without the right tools in place, you’ll face a lot of trouble accessing shipping rates that remain accurate across multiple warehouses. If your system doesn’t take into account where your inventory is located, or whether it’s located in one or multiple warehouses, it can’t give you accurate rates. Without Multi-Warehouse Management, your customers will be left with inaccurate shipping rates, which will inevitably be passed on to you. To boot, your customers might experience delivery delays if a shipment is calculated to come from one location, but ships from another.

Conclusion

When the time comes to expand to multiple warehouses, ecommerce merchants have a lot to consider. However, if the goal is expansion with a strategic plan for management, any merchant would be wise to implement a powerful multi-warehouse management system that turns every order into a piece of actionable and meaningful data.

Learn more about how ShipperHQ can help with Multi-Warehouse Management here, and learn about Bigcommerce apps that can help you master Multi-Warehouse management with a solution that’s built to seamlessly connect to your Bigcommerce store.

This article was provided by our partners at ShipperHQ.

BigCommerce helps growing businesses, enterprise brands, and everything in-between sell more online.

Start growing your ecommerce business even faster.

High-volume or established business? Request a demo