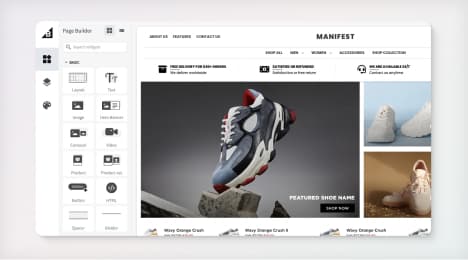

Watch Our Product Tour

See how BigCommerce helps you build and manage your online store with ease.

- Ecommerce Insights

6 Key Steps to Launch Your Online Store

Explore our Launch Foundations series to get your BigCommerce store up and running quickly.

BigCommerce helps growing businesses, enterprise brands, and everything in-between sell more online.

What Are Warehouse KPIs?

Just as you track sales figures or e-commerce metrics to monitor your business’ success over time, it’s vital to track important key performance indicators, or KPIs, in the warehouse environment. The finer points of how things are being received, handled, and shipped can reveal areas that are underproductive or need refining to be more profitable.

Monitoring these metrics month over month can help you assess whether warehouse leadership is on the right track and how the systems you’ve implemented are working. Understanding the finer points of how the warehouse is performing is an important step on the way to warehouse optimization.

Warehouse KPI Definition

In a warehouse, key performance indicators typically relate to how inventory is received and shipped, as well as the accuracy and speed of these processes. These statistics allow management to easily see how the warehouse is performing over time and if progress is being made towards larger organizational goals.

5 Critical Warehouse KPIs

Getting an accurate idea of how the warehouse operates starts by collecting the right data to analyze and draw conclusions. If you want to begin monitoring the key performance indicators of your warehouse processes, here are five KPIs that will give you a robust idea of how the most important parts of the warehouse are performing and where you can make improvements.

1. Inventory Accuracy

Keeping an accurate inventory is the first step in making your warehouse more efficient and your inventory more profitable. Many common problems, like overpaying for warehouse labor, overordering, and high storage fees start with inaccurate inventory data. The chances of issues with inventory logging are much higher if your warehouse uses a manual process to catalog the items that go in and out. Not only is the chance of human error much higher, but your team won’t be working with real-time inventory data, meaning it is not accurate from minute to minute.

2. Efficiency of Receiving

Receiving stock and logging it into inventory promptly is one of the most important tasks in the warehouse. If it’s not done properly, it can lead to pervasive problems with other warehouse operations. Monitoring the number of items received, how long it takes to enter them in the system, and the percentage of time the receiving dock is used helps paint a more accurate picture of how receiving happens daily.

If the receiving process is not meeting the goals you have in mind, implementing a barcode system can be a solution that can drive higher accuracy.

3. Picking and Packing Costs

Picking and packing are labor-intensive processes that can easily cost the organization more than they should, particularly in larger operations that employ a large staff of runners to get orders out the door. To keep an accurate idea of what picking and packing are costing you, KPIs might include the total orders picked per hour, cumulative picking labor costs, consumables usage and cost, and total cycle time for the average order.

4. Inventory Turnover

Inventory turnover measures how many times a year the warehouse cycles through its entire inventory. This number can help you determine how well your warehouse is performing compared to other companies in your industry, using the publicly available industry averages. If the inventory isn’t moving as fast as it should, you may need to revisit the buying process to ensure you’re stocking the products that meet customers demand.

5. Customer Cycle Order Time

Although the warehouse may not communicate directly with your customers, it’s a critical part of your customer-facing operation. If shipping and return times are too long, customers will notice and increase their communications with your customer service team. Checking on how long the order cycle is taking can help you predict customer satisfaction and anticipate issues before they arise.

Conclusion

Keeping warehousing costs low starts with being informed about how the warehouse operates and taking steps to adjust operations when needed. Tracking critical KPIs is one way to use the information you have to make faster and more accurate decisions. The data you collect can help you understand the weak points in your process, refine them, and keep your business profitable.

BigCommerce helps growing businesses, enterprise brands, and everything in-between sell more online.

Start growing your ecommerce business even faster.

High-volume or established business? Request a demo