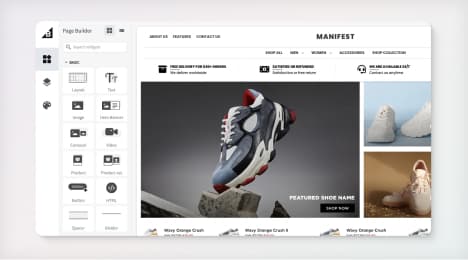

Watch Our Product Tour

See how BigCommerce helps you build and manage your online store with ease.

- Ecommerce Insights

6 Key Steps to Launch Your Online Store

Explore our Launch Foundations series to get your BigCommerce store up and running quickly.

BigCommerce helps growing businesses, enterprise brands, and everything in-between sell more online.

What is Warehouse Optimization?

The challenges of running a warehouse efficiently, with all the aspects necessary for receiving and shipping your products integrated and running smoothly, are well known in the industry. From issues with inventory control, inefficient warehouse processes, and shipping delays, these problems can result in lost profits and unhappy customers.

Warehouse optimization is a process that helps to solve many of these issues and sets your warehouse up without the problems that come from a lack of real-time data. With all of the processes that take place within the warehouse optimized, you can look forward to better results and happier customers.

What is Warehouse Optimization?

Warehouse optimization means integrating your overall processes to help determine the best way to execute and ship orders. To optimize your warehouse processes from start to finish, you must consider the most cost-effective ways to receive orders, pick the necessary items, and ship them, while also providing optimal customer service.

From the supply side of the equation, efficient handling times, inventory management, product flow, and transportation and delivery are all equally important to keeping the warehouse efficient. From the customer’s side of the equation, the warehouse must meet all delivery deadlines and handle any changes or issues that come up along the way. Once you’ve considered all of these factors, you can begin working on a warehouse optimization plan that works for your business.

The Importance of Warehouse Optimization

The warehouse acts as the sole link between the supply and demand in your business. An inefficiently managed warehouse can impact every other part of the business, from sales to customer service and even daily operations. Not only does an optimized environment help your team meet your shipping deadlines, but it also creates a safer work environment for employees who work in your warehouse. Employees can face a risk of injury in a disorganized environment with items piled up in random spaces.

Advantages to Optimizing Your Warehouse

The cost, time, and effort of implementing the technology and new processes needed to optimize your warehouse can deter you from wanting to do it. However, there are many advantages to having a fully optimized warehouse that makes the expense well worth it, including:

1. Increased customer retention rates.

With effective barcoding in place, your warehouse staff can minimize the occurrence of issues that lead to upset customers, such as late deliveries or returns that take too long to process. Once these mistakes occur, customers can be difficult to retain and may spread the story of their negative experience online. Preventing these issues from occurring is well worth the effort of implementing new technology that helps track every part of the process.

2. Effective forecasting leads to better space utilization.

Forecasting accurately what you’ll need to stock up on and what is not going to move out efficiently helps you utilize the space you have. Better space utilization leads to fewer headaches for you and saves on the expenses associated with storing unused items in the long term.

Tips for Optimizing Your Warehouse

While optimizing the warehouse environment may seem like a large task, there are easy ways to get started and gradually transform your environment, bringing increased efficiency to your supply chain over time. Some easy tips to help optimize your warehouse include:

Implement an inventory management strategy that helps automate some of the work instead of sticking with old fashioned spreadsheets or purchase order systems. This eliminates the margin of human error and reduces the expense of paying to have these tasks done manually.

Calculate and understand your total available warehouse storage space. Many business owners and warehouse managers underuse the space they have available because they simply aren’t aware of how much exists.

Optimize the physical space in the warehouse by ensuring things are clearly labeled, aisles are well lit and easy to navigate, and stocking items in order of popularity to make it easy for pickers to find items that are frequently ordered. This keeps order fulfillment moving at a fast rate and reduces the instance of workplace injuries.

As the industry becomes more integrated with new forms of technology, new tools, and processes to help solve these problems, the way warehouses are managed can involve more automation and become more efficient. Optimizing your warehouse space by going through each process and looking for efficiencies can help your business run more efficiently than ever before and having the right platform in place can help make this much easier.

BigCommerce helps growing businesses, enterprise brands, and everything in-between sell more online.

Start growing your ecommerce business even faster.

High-volume or established business? Request a demo